maxgraft® bonebuilder concept

|

As harvesting and manual adjustment of autologous bone is no longer required, donor site morbidity, operation time and costs may be reduced significantly.

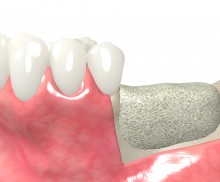

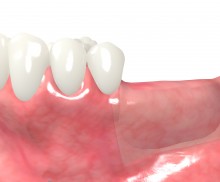

botiss virtually designs the patient matched allogeneic bone transplant based on CT/CBCT (DVT) -scans of the bone defect. The design of the bone transplant undergoes a final inspection by the clinical user before the individual order is released for production. The botiss partner, Cells+Tissuebank Austria, receives a *.stl milling file and the patient matched allogeneic bone transplant is produced under cleanroom conditions. The resulting allogeneic bone transplant is ready for insertion into the defect with only minor adjustments.

After placement, the maxgraft® bonebuilder block is fixed with osteosynthesis screws. Residual defect volume may be filled with bone regeneration material (i.e. cerabone®) and the augmentation site is covered with a collagen membrane (i. e. Jason® membrane). The strong capillary action of the three-dimensional, porous trabecular bone enables fast and efficient penetration of fluids, nutrients and blood, and reliable and predictable outcomes.